Custom CNC Machining Services

At JACO Machine Works, we take pride in being an ISO9001:2015 and AS9100D certified manufacturer of precision components and assemblies. Our custom CNC machining services cater to a wide range of industries and applications, ensuring that we deliver accurate, high-quality results that exceed your expectations while staying within your budget.

CNC Screw Machining. Our CNC screw machines are designed to produce accurate, precise, and repeatable results. With advanced features such as CNC controls, dual spindles, and live tooling, we can create parts with complex geometries in a single operation, ideal for high-volume production.

5-Axis CNC Machining. Our 5-axis CNC machines operate on five axes simultaneously, enabling the creation of intricate tool paths and the rapid production of components for complex applications like medical implants and turbines.

Vertical CNC Milling. Our vertical CNC machines are perfect for high-production and high-precision tasks. They come equipped with multi-pallet management systems, automatic tool changers, high-speed cooled spindles, and other advanced features to enhance efficiency and precision.

Horizontal CNC Milling Our horizontal CNC mills offer a fourth axis, allowing us to produce more complex parts with fewer setups compared to vertical CNC mills. This capability enhances our efficiency and precision in creating intricate components.

At JACO Machine Works, we leverage these advanced machining technologies to deliver exceptional precision and consistency in every project, ensuring that each component meets the highest industry standards.

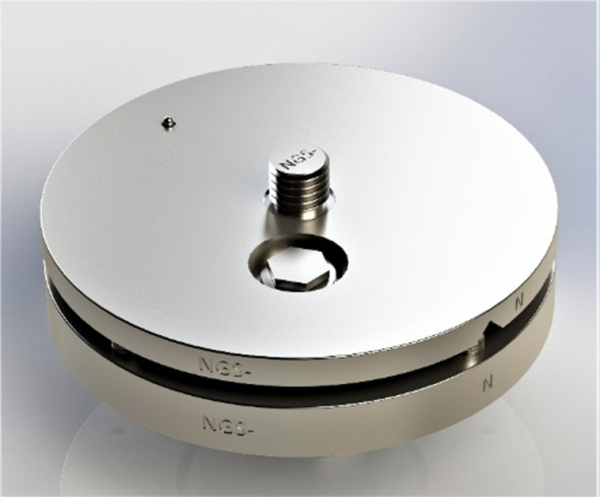

SCIGN Mount Assembly GX1000

JACO Machine Works is a leading manufacturer of SCIGN mount assemblies - our model GX1000 - which mounts a Trimble GPS antenna onto a 1-1/4” NPT male pipe threaded monument. Essential for geodetic and geophysical applications, our decades of CNC machining expertise ensure precision, durability, and reliability. Developed by the Southern California Integrated GPS Network (SCIGN), these mounts provide high precision and stability for GPS measurements. They are crucial for monitoring sea level changes and atmospheric conditions, as well as predicting earthquakes and other tectonic activities, ensuring accurate and reliable data for geodetic and geophysical research.

Secondary Services

JACO’s team of experts are equipped to meet any custom machining or manufacturing requirement through our comprehensive range of secondary services. We ensure quality in every aspect of our work, so your finished product meets all industry specifications and regulations.

3D Printing. By leveraging additive manufacturing, we create high-quality work-holding fixtures and gauges for our CNC machines. This capability allows us to expedite the production process, bringing your parts to market quickly while maintaining efficiency and competitive pricing.

Laser Welding. Our laser welding process applies heat to a small, concentrated area, joining surfaces with minimal warpage or distortion. This automated process ensures precise control and repeatability, producing high-quality welds. Laser welding is particularly beneficial for medical and surgical instruments, which require clean welds with minimal post-weld handling.

Citric Passivation. Our citric acid passivation services enhance the corrosion resistance of stainless steel in an environmentally friendly manner. This process also effectively removes surface impurities from other metals, including copper, ensuring the longevity and durability of your components. We provide free certification to ASTM A967 and A380 standards.

Design for Manufacturing. Our manufacturing engineers collaborate closely with you to provide design assistance and optimize manufacturing and production processes. We are committed to delivering exceptional customer service alongside our high-quality products and machining capabilities.

Overview of JACO Machine Works

Machining for Any Industry

With decades of CNC machining expertise serving the Silicon Valley and beyond, JACO Machine Works excels in precision manufacturing across various industries and sectors. Our robust Quality Management System, certified to ISO 9001 and AS9100 standards, ensures every component meets the highest quality benchmarks. Additionally, our QMS adheres to ISO 13485:2003 standards for medical and surgical devices, and our stringent cybersecurity measures enhance reliability and safety for aerospace and defense projects. JACO’s exceptional inventory and supply chain management guarantees timely and efficient delivery, serving a diverse range of industries from sensor components and robotic devices to surgical instruments and biotech life sciences.

.webp)