Precision Components for Any Industry

With decades of CNC machining expertise, JACO Machine Works stands out as a leader in precision manufacturing for any industry and sector. Our robust Quality management system, certified to ISO 9001 and AS9100 standards, ensures that every component meets the highest standards. Additionally, our QMS complies with ISO 13485:2003 standards for medical and surgical devices, while our stringent cyber security measures further enhance our reliability and safety for aerospace and defense projects. Meanwhile JACO’s exceptional inventory and supply chain management guarantees timely and efficient delivery, catering to a diverse range of industries from sensor components and robotic devices to surgical instruments and biotech life sciences.

Medical Devices – Our clients in the medical field are at the forefront of innovation, developing next-generation devices for pain management, orthopedic rebuilds, and replacements. At JACO Machine Works, we produce both plastic and metal components for medical devices, ranging in size from a few millimeters to over 12 inches. Our comprehensive Quality Management System (QMS) is compliant with ISO 13485 standards, ensuring the highest level of safety, reliability, and precision in every component we manufacture

Aerospace and Defense – Aerospace is a cornerstone at JACO Machine Works. With our ISO 9001 and AS9100 certification – and extensive experience in aerospace requirements, material handling, and documentation – we cater to a prestigious list of clients within the United States aerospace industry. Our commitment to cyber security compliance per NIST SP 800-171 ensures complete protection of all Controlled Unclassified Information (CUI), while our adherence to supply chain flow downs involving NADCAP suppliers guarantees the highest quality standards in our manufacturing processes.

Sensor Components and Devices - JACO Machine Works excels in producing sensor components that detect physical phenomena such as heat, light, sound, pressure, or motion, and convert them into output signals. Our state-of-the-art CNC machines and laser welding services make us a top choice for manufacturing sensors across various industries, including medical devices and aerospace.

Surgical Instruments - JACO Machine Works specializes in both invasive and non-invasive components for surgical devices and tools. We produce CNC milled and screw machined components with features such as gun drilling, laser welding, flaring, and both wire and sinker EDM. Additionally, our in-house citric passivation process, certified to ASTM A967, enhances the durability, quality, and lifespan of stainless steel components without altering machining dimensions. This process ensures that our medical and surgical equipment meets the highest standards of cleanliness and corrosion resistance, making it ideal for tight-tolerance applications.

Robotic Components - The robotics industry, including robotic surgery, presents unique challenges. At JACO, we leverage our expertise and state-of-the-art equipment to provide components that meet the stringent standards required. We excel in prototype manufacturing and offer comprehensive Design for Manufacturing (DFM) services. This ensures that our clients developing production sensors, actuators, end effectors, drives, and controllers receive optimized, high-quality robotic components tailored to their specific needs.

BioTech and Life Sciences - The life sciences market, encompassing the study of humans, plants, animals, organisms, and genetics, is a critical sector in both research and manufacturing. Our clients, ranging from start-ups to established companies, rely on JACO’s expertise to deliver high-quality components for applications such as DNA analysis, medical diagnostics, and single-cell manipulation. We specialize in machining alloys with properties like corrosion resistance, high temperature tolerance, low thermal expansion, and linear elasticity, ensuring our components meet stringent industry requirements.

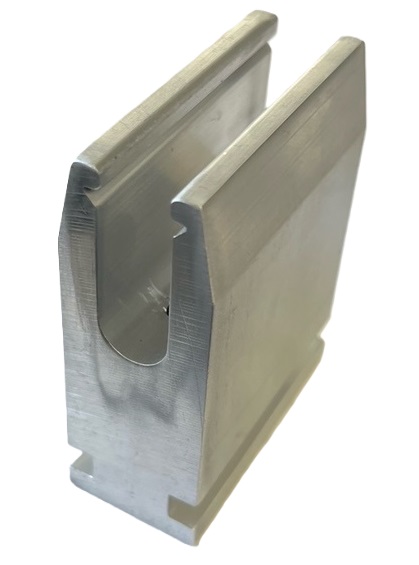

High Performance Electrical Connectors - JACO Machine Works excels in machining critical components for high-performance electrical connectors, including fork connectors, sockets, modular connectors, and busbars, essential for high voltage applications in both aerospace and telecommunications. These components, made from materials like aluminum, brass, copper, and PEEK plastic, are designed for enhanced conductivity, durability, and reliability. Our rigorous quality control processes guarantee each component meets stringent industry standards supporting the emerging green economy.

High Performance Electrical Connectors - JACO Machine Works excels in machining critical components for high-performance electrical connectors, including fork connectors, sockets, modular connectors, and busbars, essential for high voltage applications in both aerospace and telecommunications. These components, made from materials like aluminum, brass, copper, and PEEK plastic, are designed for enhanced conductivity, durability, and reliability. Our rigorous quality control processes guarantee each component meets stringent industry standards supporting the emerging green economy.

Semiconductor Equipment and Tooling - JACO Machine Works specializes in machining high-purity components for the semiconductor industry, using materials like vacuum re-melt 316L stainless steel and Hastelloy. These materials ensure minimal contamination and optimal performance in semiconductor applications. JACO produces critical parts such as heat sinks for gas lines, manifolds for gas delivery weldments, and blocks for Electrostatic Chuck (ESC) systems, all designed to meet stringent cleanliness and precision standards. Our advanced capabilities and commitment to quality make JACO a trusted partner in the semiconductor industry.

The Best Machining Services for Precision Components

Whatever your application might be, our engineers at JACO are happy to help bring your product to market in the shortest amount of time and at the lowest cost possible. We are committed to providing you with quality engineering, design services, and supply chain management that will exceed your expectations and meet every specification. Please follow the below links to learn more about our machining and welding capabilities:

Whatever your application might be, our engineers at JACO are happy to help bring your product to market in the shortest amount of time and at the lowest cost possible. We are committed to providing you with quality engineering, design services, and supply chain management that will exceed your expectations and meet every specification. Please follow the below links to learn more about our machining and welding capabilities:

- 5-Axis Precision Machining

- CNC Swiss Screw Machining

- Vertical CNC Machining

- Horizontal CNC Machining

- Laser Welding

Contact us or Request a Quote to get started on your project today!