Plastics

Industrial Uses

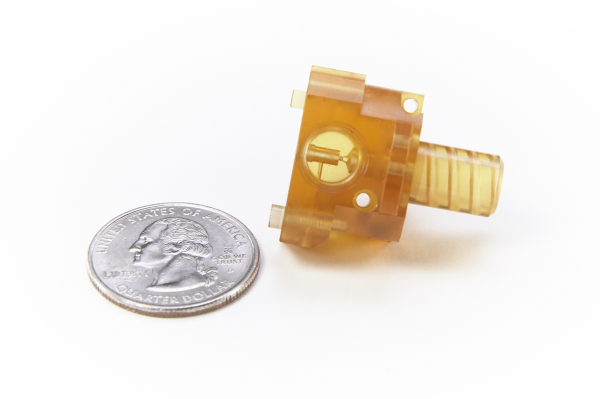

In addition to its use in general manufacturing, plastics have carved out a significant role in the medical, aerospace, sensor device, and life sciences industries due to their remarkable versatility. Engineers and designers can tailor the properties of plastics, such as strength, transparency, and chemical resistance, to meet the specific needs of these applications. This adaptability further underscores the indispensable role of plastics in modern industry and technology.

Medical Devices: The biocompatibility and versatility of plastics make them ideal for use in implantable devices – such as hip and knee joint replacements – which often incorporate high-performance polymer components. Additionally, plastics’ lightweight nature, ease of sterilization, and corrosion resistance make them a preferred choice for surgical instruments, ranging from syringes to surgical tools.

Sensor Devices: In the sensor device industry, plastics are equally vital. Their inherent properties of strength, transparency, and chemical resistance make them ideal for use in sensor devices and transducers. These devices, often used for measuring physical quantities such as pressure, temperature, and force, benefit from the durability and adaptability of plastics.

Aerospace and Defense: Plastics play a pivotal role in the aerospace and defense sectors due to their lightweight nature, strength, and resistance to heat and chemicals. They are used in the construction of various components of aircraft and spacecraft, including navigational function components, structural elements, and interior parts.

Life Sciences: Plastics are prevalent in laboratory settings. They are used in a variety of applications, from bioreactors and cell culture flasks to scaffolds for tissue engineering. Furthermore, plastic consumables, such as PCR tubes and microfluidic chips, play a crucial role in facilitating genetic research and diagnostics.

Plastics JACO Machines

Delrin®, Acetal, POM (Polyoxymethylene)

Delrin® - also known as Polyoxymethylene (POM), Acetal, or Duracon® - is utilized for crafting precision components that require high rigidity, minimal friction, and superior dimensional stability. In the aerospace industry, Delrin is commonly used for mechanical parts like gears, fittings, and bearings due to its excellent strength, durability, and temperature resistance. In the medical field, specific grades of Delrin meet requirements for use in medical devices and pharmaceutical processing equipment. Its electrical properties also make it suitable for use in electrical applications, including electrical connectors.

Attributes and properties of Delrin include:

Attributes and properties of Delrin include:

- Dimensionally stable

- Easy to fabricate and manufacture

- Readily available in rod, sheet and tube stock

- Strong lubricity for bearings and wear surfaces

- Impressive Mechanical Strength

- Resistant to Fatigue

- Impervious to exposure to moisture, gas and chemical solvents

- Stable in low temperatures

PEEK, or polyether ether ketone, is a type of plastic that is highly resistant to heat and chemicals, while also exhibiting excellent mechanical properties. In the medical device industry, PEEK is used extensively due to its biocompatibility, low moisture absorption, and superior fatigue properties. In the realm of electrical connectors, PEEK’s high mechanical strength, resistance to hydrolysis, and low moisture absorption make it an ideal choice. Its use in wire coating and semiconductor wafer carriers further underscores its versatility.

Attributes and properties of PEEK include:

- Low weight – High strength plastic

- UL 94 V-0 flammability rating

- Great chemical resistance even at higher temperatures

- Strong, stiff material - holds up well to stress and crack resistant

- Great in hot water, steam and other harsh environments

- In medical devices, PEEK can be steam sterilized, autoclaved, etc.

- Some grades approved for food industry use

- Machining and turning friendly

- Low smoke emission when exposed to flame

Ultem® (poly ether imide or PEI)

Parts made from PEI, or polyetherimide, are integral to many programs and product lines. This high-performance plastic is utilized in various industries - including medical, scientific, electrical and sensor devices - due to its strength and rigidity. Ultem® is also the high-performance thermoplastic of choice for many aerospace and aircraft applications. It exhibits natural flame resistance and extremely low smoke generation.

Attributes and properties of Ultem® include:

- Resistant to environmental forces while being easily fabricated and bonded

- Retains rigidity and strength in high temperatures

- Flame retardant

- Electrical properties – some of the highest dielectric strengths of any thermoplastic

- Resistant to hot water and steam; can withstand repeated cycles in a steam autoclave

|

ABS (Acrylonitrile Butadiene Styrene) ABS is a cost-effective thermoplastic widely utilized across various industries when a non-metallic, general-purpose material is required. Known for its excellent balance of durability, heat resistance, and chemical resistance, ABS exhibits high mechanical strength and rigidity. Attributes and properties of ABS include:

|

Lexan – PC (Polycarbonate) Lexan, a type of polycarbonate, is a strong, lightweight plastic. With 30 times the impact strength of acrylic and 250 times that of glass, Lexan is practically unbreakable. Its strength and lightness make it ideal for high-performance industries like aerospace components and automotive parts. Attributes and properties of Lexan include:

|

|

Acrylic – Plexiglass Acrylic, or plexiglass, is a durable and transparent thermoplastic. It serves as a good alternative to glass due Attributes and properties of Acrylic include:

|

Teflon (PTFE – fluoropolymer) Teflon, a fluorocarbon-based polymer, is known for its high resistance to solvents, acids, and bases, as well as its excellent weather resistance and electrical properties. In electronics, it is valued for its dielectric properties, while its biocompatibility and chemical resistance make it ideal for medical devices and surgical instruments. Attributes and properties of Teflon/PTFE include:

|

|

Nylon – Polyamide (PA) Nylon, or polyamide, is a versatile, durable polymer with excellent mechanical properties like high tensile strength, high impact strength, flexibility, low creep, and toughness. Its thermal and electrical resistances make it ideal for electronic components and automotive insulation. Attributes and properties of Nylon include:

|

|

If you’re developing plastic machined components, JACO Machine Works is ready to review your program and offer support. No matter your application, our skilled engineers and operations professionals are dedicated to helping you succeed.

Contact us or Request a Quote today!