Precision Parts Machining & Engineering Capabilities

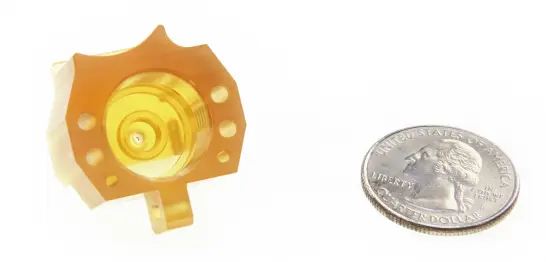

JACO Machine Works stands as an industry leading ISO9001:2015 & AS9100D certified precision CNC manufacturer. Through our use of advanced technology and state-of-the-art equipment, we provide high-quality precision components and assemblies for all our customer’s critical applications.

We offer a wide range of precision CNC Manufacturing services for short and long-run production, including Design for Manufacturing, precision CNC turning and swiss screw machining, solid modeling, CAD Detailing, and Custom 3D printing. Our engineers provide a variety of skills and capabilities, including:

- CNC and Swiss Screw Machining – Renowned for their accuracy, precision, and high repeatability, CNC screw machines particularly excel when it comes to machining small parts in medium to high volume.

- 5-Axis CNC Machining – 5-Axis machining elevates versatility by enabling precision machining across five axes within a single setup. This advanced technique delivers unparalleled efficiency and empowers the production of intricate designs and complex geometries.

- Horizontal CNC Milling – our Horizontal Milling Centers (or HMCs) provide repeatability for cost-effective machining of complex, high-volume projects.

- Vertical CNC Milling – our Vertical Milling Centers offer versatility in machining, excelling at tasks such as slot cutting, drilling, and face milling.

- Laser Welding - our precise Laser Welding equipment creates highly accurate, circumferential welds with minimal heat-warping, offering a cost-effective solution for cleanly joining components with complex geometries.

Not sure which service best suits your needs? Contact an expert at JACO online and let us find a solution for you.

CNC Manufacturing Industry Expertise

JACO Machine Works leverages multi-generational expertise, a robust Quality Management System, ability to work with a wide variety of metals and plastics, skilled machinists, and cutting-edge manufacturing tools to give our customers across various market sectors the competitive edge they need to thrive.

As a leading precision manufacturing company, we serve diverse industries including:

- Aerospace and Defense

- Medical Devices

- Surgical Instruments

- Sensor Devices

- High Performance Electrical Connectors

- Semiconductor Tooling and Equipment

- Robotics

- Biotech & Life Sciences

- And more!

Our commitment extends to adopting and utilizing the most advanced equipment and technology available, ensuring optimal efficiency, uniformity, and top-notch quality. With a team of highly skilled machinists, programmers, and engineers, JACO Machine Works consistently meets and exceeds our customers’ demands.

Explore our shop featured in the video below!

CNC Finishing Processes

JACO Machine Works provides an array of finishing processes to ensure the highest quality for our parts, including but not limited to:

- Laser Welding

- In-House Citric Passivation

- Ultrasonic Cleaning

- 3D Printing

- Centrifugal and Vibratory Tumbling

- Bead Blast

- Heat Treat

- Plating, Powdercoating, and more!

Our well-managed network of qualified suppliers enables us to meet even the most complex out-processing and testing requirements.

CNC Machining Technology and Software

Our cutting-edge technology and software resources empower us to design, program, and inspect complex part geometries directly from our customers’ solid model part files. This streamlined process enables us to achieve rapid, repetitive production and inspection while maintaining a cost-effective approach. Information technology and software systems at JACO include:

| JobBOSS® | ERP software that manages our shop including quoting, purchasing, routing, scheduling, inventory, shipping, and costing |

| Solidworks® Modeling | 3D mechanical design system for product development, fixture and tool design |

| Solidworks® Inspection | An inspection tool for direct data collection and analysis |

| Simpletrak® | Our quality system management tool with record keeping. Certified to AS9100D and ISO9001 |

| GibbsCAM® | Solids-based tool path generation for 3-, 4- and 5-Axis milling machines |

| Autodesk Partmaker® | Solids-based tool path generation for mulit-axis turn-mill and CNC Swiss screw machines |

Quality Precision Machining Services

At JACO Machine Works, we maintain a robust Quality Management System and employ advanced inspection technology to ensure consistent product conformance, accurate reporting, and full lot traceability at every production stage. Our Quality Assurance team conducts in-process part inspections, leveraging real-time shop-floor data collection and innovative functional gauging designs. Our experienced inspectors and engineers offer the following services and capabilities:

| Zeiss Contura and Mitutoyo CMM Inspection |

Precise measurements using cutting-edge coordinate measuring machines. |

| Surface Finish Testing | Ensuring impeccable surface quality. |

| Statistical Process Control | Monitoring and maintaining process stability. |

| Validation Reporting | In-Process, First Article and OQ/PQ Validation Reporting |

| Certification | Demonstrating compliance and excellence |

Lean Production Management for CNC Machining

Supply chain professionals have a lot to manage, especially in today’s fiercely competitive markets. To alleviate stress, mitigate risk, and streamline supply chain management, JACO Machine Works offers a single point of contact for all our customers. As a critical supplier to the Aerospace and Medical Device sectors, our value-added inventory and supply-chain management services ensure that orders remain on schedule and within budget. We excels in implementing and managing strategies such as Demand Flow and Just-In-Time (JIT) Delivery.

For more information, explore our vendor-managed inventory solutions or connect with a JACO representative online.

Machining Services for Most Materials

With decades of precision machining expertise, our CNC machining centers excel at producing high-precision parts across various materials, such as: Stainless steel, Aluminum, Copper, Brass, Titanium, Plastics and others.

Following the below links for detailed information about the specific materials we work with:

Contact the Experts at JACO Machine Works

As an ISO9001:2015 & AS9100D certified precision manufacturer, we at JACO Machine Works prioritize rigorous quality control, continuous process improvement, and thorough document control throughout production. Our unwavering commitment to Quality Assurance, Lot Traceability, and certification underscores our dedication to customers. In short - when it comes to precision CNC machining, JACO is your trusted partner. Contact us or Request a Quote today for all your machining needs!